UPDATE 2: Document structure and basic tools

-

UPDATE: Ulrich has developed an

unfolding algorithm that can be used as a macro.

-

Some things have changed since

sheet metal part 1, where, for example, faces were classified by being flat or cylindrical, or folds only counted if their angle was 90º.

Even thought the algorithm is not finished (current problem is being discussed

here), the new approach I'm going to explain here is more robust and is not even limited to face geometry or fold angles. You can even do folds with different radius, this face classifier can withstand it.

This is the part I'm going to use as example:

It has been created using

this script, and you can download it

here.

The workflow that I have in mind to unfold a part is:

- Select the face that will behave as base (all faces will be unfolded over the plane by it described )

- Run the script.

Let's start.

Import the libraries:

As always, we need to import some library. The only one we need is "Gui", from the main FreeCAD library. In addition, we set the thickness of the sheet:

from FreeCAD import Gui

thk = 1.0

Retrieve user selection:

This is a basic command very useful at writing macros:

# Get Selected Shape and Face

SelObject = Gui.Selection.getSelection()[0].Shape

SelFace = Gui.Selection.getSelectionEx()[0].SubObjects[0]

SelObjects contains the selected shape and SelFace contains the selected face. Note that user only needs to click on the face and with that we can take the whole object.

Get ride off non useful faces:

The action starts here, but first: Which are the non-useful faces?

They are the ones marked in green at the picture:

This faces are not needed because they do not store useful geometry data. To clear things in a future, we are going to create a list excluding this faces:

faceList = [] # Create an empty list that will hold the filtered faces

for face in SelObject.Faces:

apnd = True

for edge in face.Edges: # Measure length of all edges from all faces

if abs( edge.Length - thk ) < 0.001: #tolerance because float point things

apnd = False # If edge length is equal to thickness, do not append it.

break

if apnd: # If the face hasn't any edge with length == thickness, append it.

faceList.append( face )

Did it work? Is something easy to test: select a face from the object and paste at FreeCAD's python console all the code.

Then, do:

len( SelObject.Faces )

len( faceList )

The first one gives "46" and the second "18". That's a great data reduction!

Unfold tree: step 1

We have a list containing only meaningful data, but this data is duplicated. Why?

Is duplicated because the faces selected in the first picture (back of the part) are parallel to the faces on the second picture (top of the part). While is easy to create another filter to remove the repeated faces, is very hard to not lose the connection between faces with it.

So we are going to create a list containing wich face links to wich face or group of faces. This list has this form:

index A B C D E F

"list" = [ [B],[A,C,D],[B], [B,E,F], [D], [D] ]

The index number belongs to the position in "faceList" of the face. The content under the index are the faces linked to that face.

To explain it better, "list" is the solution to faces links of this simplified part:

So how we create a list like that one?

Just run this little "monster":

# auxiliar function: find face number (index) in faceList:

def gfN( inFace ):

SF_COM = inFace.CenterOfMass

SF_NOR = inFace.normalAt( 0, 0 )

for n in range( len( faceList ) ):

F_COM = faceList[n].CenterOfMass

F_NOR = faceList[n].normalAt(0,0)

if SF_COM == F_COM and SF_NOR == F_NOR:

break

return n

# get selected face position (index) in faceList:

SelFaceNumber = gfN( SelFace )

# auxiliar function: get faces linked to input face (returns position in faceList )

def gfR( inFaceN ):

temporalList0 = []

inFace = faceList[inFaceN]

for inEdge in inFace.Edges:

if str( inEdge.Curve )[1:5] == "Line":

P_ia = inEdge.valueAt( 0.0 )

P_ib = inEdge.valueAt( inEdge.Length )

V_0 = ( P_ib - P_ia )

for n in range( len( faceList ) ):

if n != inFaceN:

face = faceList[n]

for edge in face.Edges:

P_a = edge.valueAt( 0.0 )

P_b = edge.valueAt( edge.Length )

V1 = P_b - P_ib

V2 = P_a - P_ia

condition0 = abs( ( V_0.cross( V1 ) ).Length ) < 0.0001

condition1 = abs( ( V_0.cross( V2 ) ).Length ) < 0.0001

if condition0 and condition1:

faceNumber = gfN( face )

temporalList0.append( faceNumber )

break

# clean from repeated faces

temporalList1 = []

for i in temporalList0:

if not( i in temporalList1 ):

temporalList1.append( i )

return temporalList1

compFaceRel = []

for fn in range( len( faceList ) ):

data = gfR( fn )

compFaceRel.append( data )

If you run the code above, and then type "comFaceRel" you should see something like:

[[3, 2], [4, 5], [0, 3, 6], [0, 7], [1, 8], [1, 4, 9], [2], [3, 10, 11], [4], [5, 12, 13], [7, 14], [7, 10, 15], [9, 13, 16], [9, 17], [10], [11], [12], [13]]

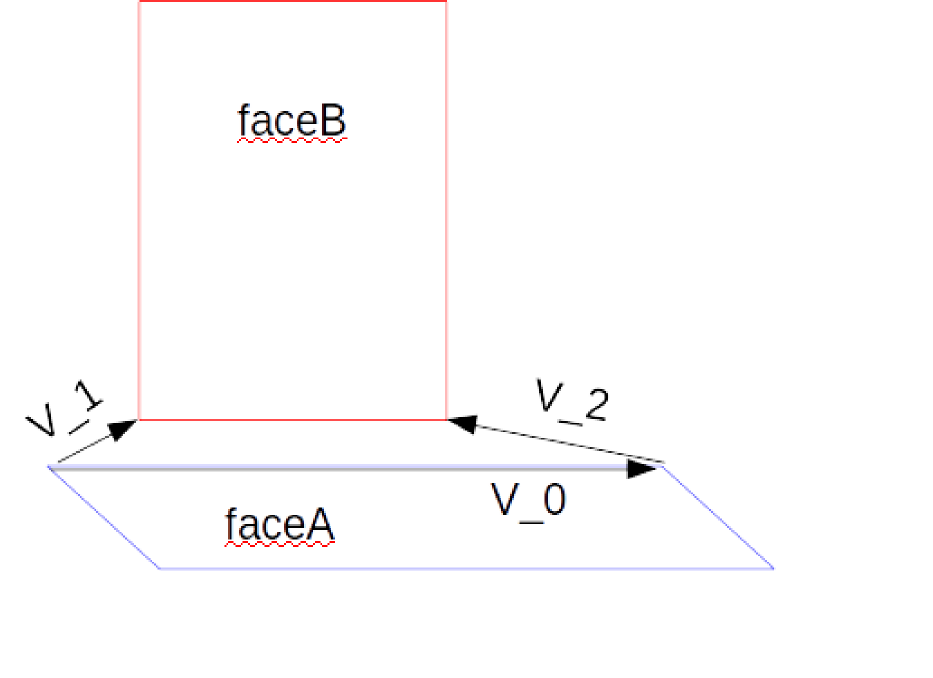

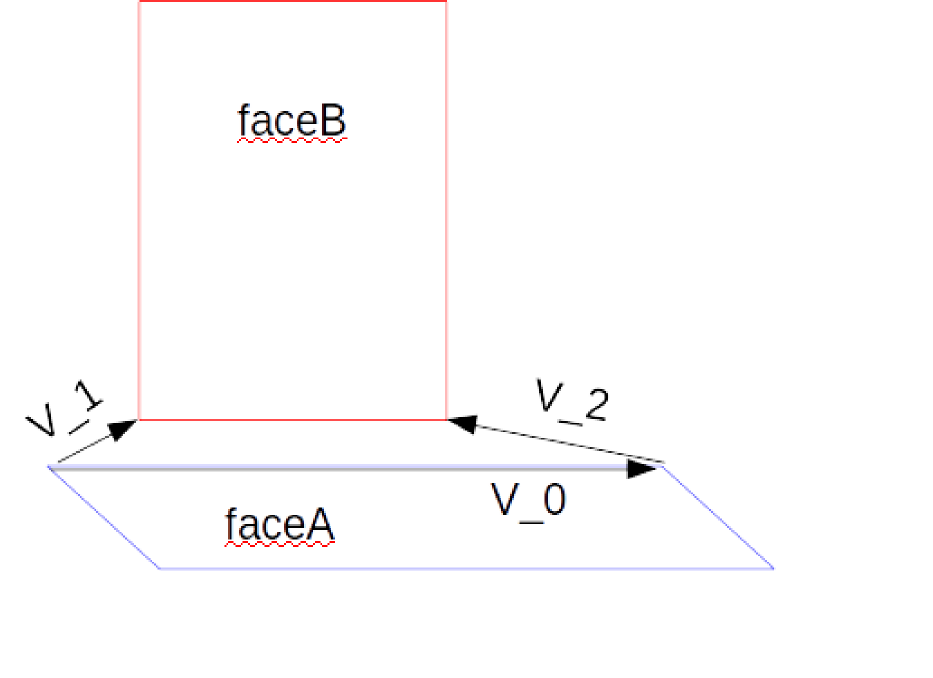

How a link is recognized:

faceA is the current face being analyzed to inspect its links. FaceB is one of all the faces contained in facesList suspicious of being linked with faceA.

V_0 the director vector of the current edge of faceA being inspected. V1 and V2 are vectors going from the end-points of the edge from faceA to the end-points of an edge owned by faceB.

A face is linked if the cross products V1xV0 and V2xV0 have a length of 0.

All this is calculated inside the previous function "gfR".

At the moment, this is the current state of the sheet metal workbench. Next step is to get the link between final nodes of the tree of faces to the selected face to unfold.

Taking the previous example model with faces A, B, C..., the needed list previous to unfold is, with B as unfold base:

[ [A,B], [C,D], [F,D,B], [E,D,B]]

Knowing that list would be the major step forward. With it, the unfold algorithm would be almost finished.

Complete code:

# JMG december 2014

from FreeCAD import Gui

thk = 1.0

# Get Selected Shape and Face

SelObject = Gui.Selection.getSelection()[0].Shape

SelFace = Gui.Selection.getSelectionEx()[0].SubObjects[0]

# remove faces placed on the thickness

faceList = [] # Create an empty list that will hold the filtered faces

for face in SelObject.Faces:

apnd = True

for edge in face.Edges: # Measure length of all edges from all faces

if abs( edge.Length - thk ) < 0.001: #tolerance because float point things

apnd = False # If edge length is equal to thickness, do not append it.

break

if apnd: # If the face hasn't any edge with length == thickness, append it.

faceList.append( face )

# auxiliar function: find face number (index) in faceList:

def gfN( inFace ):

SF_COM = inFace.CenterOfMass

SF_NOR = inFace.normalAt( 0, 0 )

for n in range( len( faceList ) ):

F_COM = faceList[n].CenterOfMass

F_NOR = faceList[n].normalAt(0,0)

if SF_COM == F_COM and SF_NOR == F_NOR:

break

return n

# get selected face position (index) in faceList:

SelFaceNumber = gfN( SelFace )

# auxiliar function: get faces linked to input face (returns position in faceList )

def gfR( inFaceN ):

temporalList0 = []

inFace = faceList[inFaceN]

for inEdge in inFace.Edges:

if str( inEdge.Curve )[1:5] == "Line":

P_ia = inEdge.valueAt( 0.0 )

P_ib = inEdge.valueAt( inEdge.Length )

V_0 = ( P_ib - P_ia )

for n in range( len( faceList ) ):

if n != inFaceN:

face = faceList[n]

for edge in face.Edges:

P_a = edge.valueAt( 0.0 )

P_b = edge.valueAt( edge.Length )

V1 = P_b - P_ib

V2 = P_a - P_ia

condition0 = abs( ( V_0.cross( V1 ) ).Length ) < 0.0001

condition1 = abs( ( V_0.cross( V2 ) ).Length ) < 0.0001

if condition0 and condition1:

faceNumber = gfN( face )

temporalList0.append( faceNumber )

break

# clean from repeated faces

temporalList1 = []

for i in temporalList0:

if not( i in temporalList1 ):

temporalList1.append( i )

return temporalList1

compFaceRel = []

for fn in range( len( faceList ) ):

data = gfR( fn )

compFaceRel.append( data )

Bye!